Product Description

The FS series single shaft shredder mainly consist of the rotor knives spindle, counter knives, the feed hopper, the hydraulic feeding system, the power system and PLC automatic control system.It has the following advantages: strong power, high – efficiency processing capabilities, durable blades, an intelligent control system, and an energy – saving and environmentally friendly design.It is widely applied in industries such as solid waste treatment, renewable resource recycling, plastic processing, rubber processing, electronics processing and so on.

With its outstanding performance and reliable quality, it has successfully passed a number of international authoritative certifications such as the EU CE. The product is sold well in many countries and regions around the world, including South Korea, Malaysia, the Philippines, Iraq, the United Kingdom, Brazil, etc., winning the high trust and praise of global customers. Choosing our single – shaft shredder means choosing an efficient, stable, and environmentally friendly material processing solution. Let’s join hands to create a beautiful future of sustainable development.

Product Specifications

| Model | FS600 | FS800 | FS1000 | FS1200 | FS1400 | |

| Power of Main Motor(kW) | 22~30 | 45 | 55 | 75 | 110 | |

| Hydraulic Pump Power(kW) | 3 | 4 | 4 | 5.5 | 5.5 | |

| Reducer Model | H4 | H5 | H6 | H8 | H9 | |

| Power Control Cabinet | PLC Intelligent Control System (Chint, Delixi, ABB, Siemens are available for optional configuration) | |||||

| Rotor Knives | Size (mm) | 40*40/35*35 | ||||

| Quantity (pcs) | 30/36 | 38/48 | 46/60 | 58/72 | 62/87 | |

| Counter Knives | Size (mm) | 300*100 | 400*107 | 500*113 | 600*120 | 472*127 |

| Quantity (pcs) | 2 | 2 | 2 | 2 | 3 | |

| Spindle Diameter (mm) | 140 | 150 | 170 | 180 | 190 | |

| Cutter Diameter (mm) | 260 | 300 | 300 | 350 | 400 | |

| Rotary Diameter (mm) | 300 | 350 | 350 | 400 | 450 | |

| Size(m) | 2.2*1.4*1.7 | 2.8*1.7*1.9 | 3.1*1.9*2.2 | 3.5*2.0*2.4 | 4.1*2.4*3.1 | |

| Whight(kg) | 2850 | 3900 | 5100 | 6200 | 8700 | |

| Note | Customizable. According to customers’ requirements, the drawings will be redesigned and non-standard products will be manufactured. | |||||

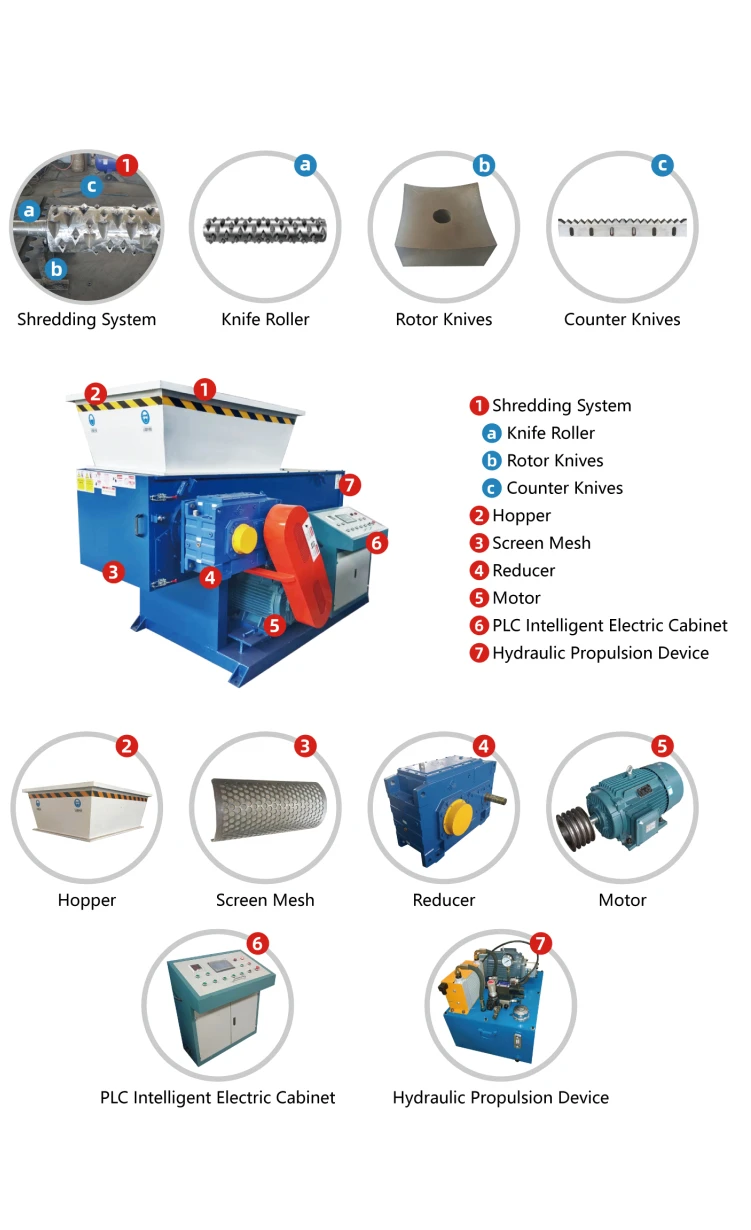

Composition and Structure

01

Cutter Shaft Structure

The main shaft is made of high-strength alloy steel. It undergoes precision machining and heat treatment processes to enhance its wear resistance, corrosion resistance, and fatigue resistance.

The blade is made of DC53 material. Through special heat treatment and surface coating processes, the service life and shreddering performance of the blade are improved.

There are multiple keyways or threaded holes on the main shaft for installing the blades. Bearings are installed at both ends to ensure the rotation accuracy and stability of the main shaft.

02

Screen Structure

The screen mesh is made of high – quality metal materials to ensure its strength, wear resistance and corrosion resistance.

The size of the screen holes depends on the discharging requirements, and different screen meshes can be customized according to specific requirements.

The screen mesh is fixed at the discharge port with bolts, which is convenient for disassembly and replacement.

03

Power Drive System

The power system consists of a motor and a speed reducer.

The motor power options include 22kW, 45kW, 75kW, 90kW, 132kW, etc. Motors with corresponding power can also be provided according to specific requirements.

The Guomao hardened – tooth – surface reducer is adopted, which is characterized by high transmission efficiency, strong load – bearing capacity, and low noise.

04

Hydraulic Propulsion System

The material pusher structure is powered by a hydraulic pump, featuring continuous and stable working efficiency as well as a long service life.

The original hydraulic tank refrigeration system enables operation in various harsh climates.

05

PLC Control System

The PLC control system is easy to operate and has functions such as intelligent control, fault alarm, and emergency stop switch.

The brand of electrical components is Delixi. It can also be changed to brands like Siemens or Schneider according to requirements.

Product Features

High – efficiency and Energy – saving

The FS single shaft shredder is equipped with top – quality alloy blades. The material of the rotor knives are DC53, and that of the counter knives are D2, matched with a sturdy and durable body structure, it ensures that all kinds of materials can be shredded into small pieces quickly and accurately during operation, greatly improving production efficiency. Meanwhile, by introducing an advanced power system and combining innovative energy – recovery technology, the energy consumption is effectively reduced, enabling the equipment to operate stably with low energy consumption and high efficiency. This not only reduces production costs but also conforms to the development trend of environmental protection and energy conservation.

Safe and Reliable

The FS single shaft shredder is equipped with a PLC intelligent electronic control system and multiple safety protection devices, such as emergency stop buttons and protective covers, to ensure the safety of operators.

Controllable Discharge Size

According to the actual needs of users, the size of the shredded materials can be controlled by adjusting the aperture of the screen mesh or the blade configuration.

Low Noise

The FS single shaft shredder operates with relatively low noise, which is conducive to improving the working environment.

Easy Maintenance

Main components such as rotor knives, counter knives, and screen meshes can be independently disassembled, installed, and replaced, which further improves the convenience of equipment maintenance.

Customizable

Besides the factory – standardized equipment, customized products can also be offered in line with customers’ requirements, including extra – large – scale equipment, electrical component brands, motor power ratings, rotor knives dimensions, etc.