Product Description

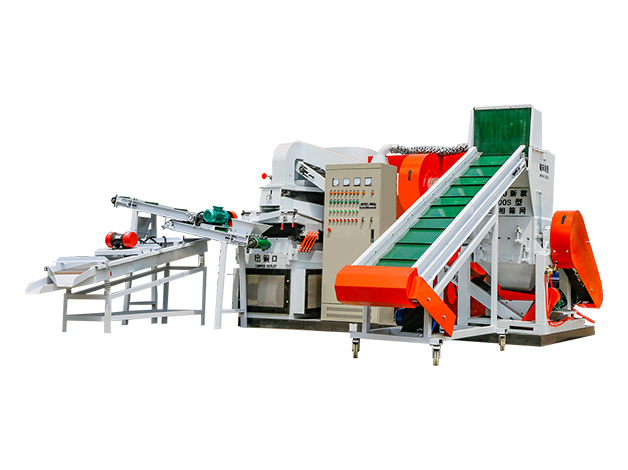

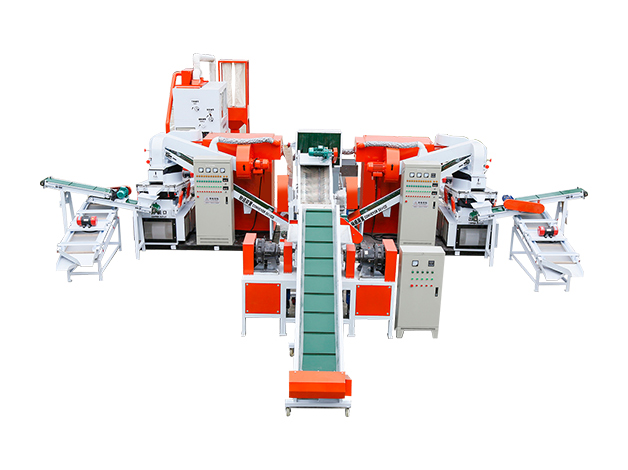

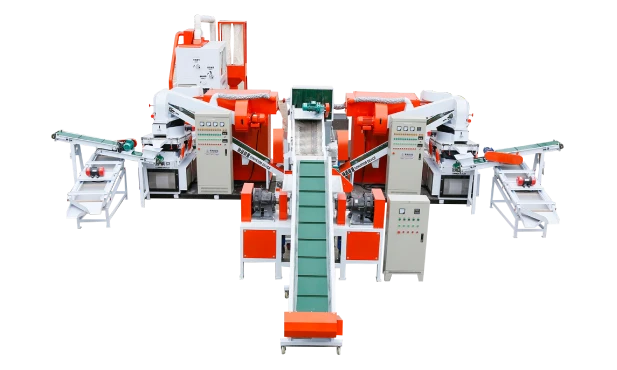

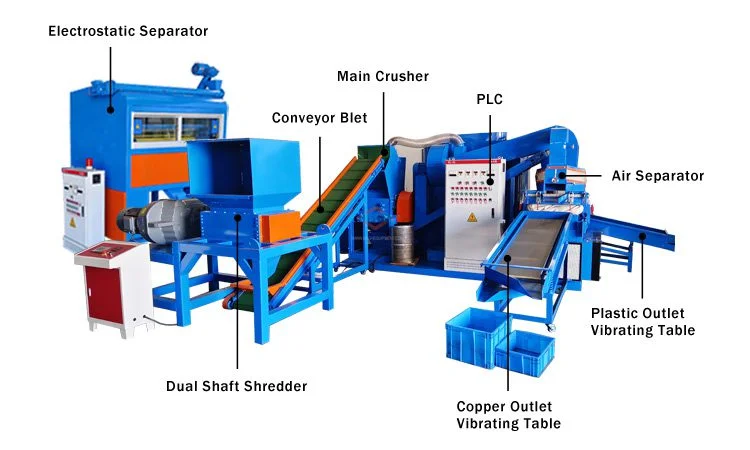

The FC series copper wire crusher, also known as waste wire recycling and processing equipment, is an environmentally – friendly mechanical device. Through five systems, namely the feeding system, crushing system, screening system, separation system, and discharging system, it can separate copper from plastics in waste wires, circuit wires, miscellaneous wires, communication wires, data cables, headphone wires, etc.

Our equipment has advantages such as reasonable price, compact structure, advanced technology, high output, and a high copper – plastic separation rate. It has passed multiple certifications including the EU CE certification, and is an ideal equipment for crushing and separating waste wires. It has been sold far to many countries and regions around the world, like the Philippines, Vietnam, Malaysia, Chile, etc., and has won high recognition from international customers.

Product Specifications

| Model | STC400 | STC600 | STC800 | STC1000 | |

| Processing Range (mm) | 0.5-20 | ||||

| Motor Power (kW) | 27 | 37 | 45 | 55 | |

| Output (kg/h) | 150-180 | 400-600 | 500-700 | 600-800 | |

| Weight(kg) | 2800 | 5000 | 6000 | 7000 | |

| Size(cm) | 320*210*230 | 750*480*300 | 820*00*300 | 880*500*300 | |

| Note | Customizable. According to customers’ requirements, the drawings will be redesigned and non-standard products will be manufactured. | ||||

Composition and Structure

Product Features

Accurate Automated Control

Our equipment is controlled by a PLC program. It has a uniform feeding mechanism, and each system is equipped with an automatic alarm device, ensuring the equipment operates more accurately and stably.

Simple Safe Operation

It features an aesthetically pleasing appearance, ensuring safety and reliability. The operation is straightforward, requiring only one operator throughout the process. There is no need for complex installation; it can be used as soon as it is powered on.

Compact Integrated Design

Both the sorting equipment and the dust – collecting equipment are installed on one platform. This not only saves floor space but also makes it convenient for operators and reduces the operation time.

Efficient Quiet Shredding

The shredding system adopts either the FS single shaft shredder or the FD double shaft shredder independently produced by our company. These shredders are characterized by higher efficiency, lower noise and safer operation.

High Sorting Accuracy

The high – precision air separator is adopted, and the sorting accuracy rate is over 99%.

Effective Dust Collection

Pulse dust – collecting bags are adopted, and the dust removal efficiency is over 99%.

Customizable Product Options

In addition to the standardized equipment in the factory, customized products can also be provided according to customers’ special requirements, such as the models of shredders, separators, and dust collectors, the brands of electrical components, and the power of motors.