Product Description

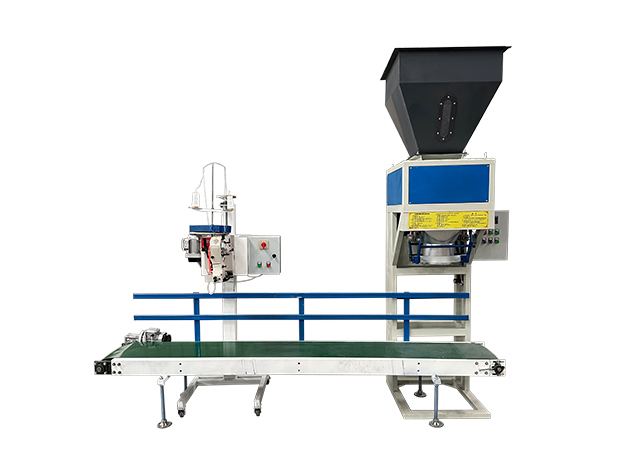

The FP series packaging machines come in various models such as granular, powder, bulk bag, and double – station types. They are widely used for packaging a variety of materials, including plastic, rubber, and biomass granules, grain seeds, non – staple foods, feeds, fertilizers, ore powder residues, river sand, etc.

Designed in accordance with national GMP standards, it integrates machinery, electricity, optics, and instrumentation. It has functions such as automatic quantitative measurement, automatic filling, over – weight error alarm, and automatic adjustment of measurement errors. It boasts advantages like high precision, high speed, high torque, and long service life. Moreover, our machines have been sold to many countries and regions around the world, including Malaysia, Vietnam, Russia, Côte d’Ivoire, Tanzania, etc., winning high recognition from international customers.

Product Specifications

| Model | Granule Packaging Machine | Powder Packaging Machine | Ton Bag Packaging Machine | ||

| FP-G5 | FP-G50 | FP-P5 | FP-P50 | FP-T500 | |

| Packaging Scope(kg) | 0.1~10 | 10~60 | 0.1~10 | 10~60 | 500~1000 |

| Packaging Speed(bag/min) | 6~12 | 200~240 | 6~25 | 180~240 | 10~45(bag/h) |

| Packaging Accuracy | ≤±1‰ | ≤±2‰ | ≤±1‰ | ≤±2‰ | ±1‰~±5‰ |

| Power (kW) | 2 | 0.92 (excluding air compressor) | 5 | 1.67 (excluding air compressor) | Be based on reality. |

| Air Pressure (Mpa) | / | 0.6 | / | 0.6 | 0.4 – 0.6 |

| Note | Customizable. According to customers’ requirements, the drawings will be redesigned and non-standard products will be manufactured. | ||||

Product Features

Stainless, Touchscreen, Easy

Made of stainless – steel material and equipped with a touch – screen PLC display, it is easy to operate and understand.

Dual Switch Options

With the dual options of photoelectric switch and foot switch, there is a wide range of choices.

Open, Cleanable Design

Featuring an open – type design from multiple angles, it enables quick cleaning.

Electronic, Precise, Stable

Measured directly by an electronic scale, it has strong anti – interference ability.

Multi-Industry Applicable

It has a wide range of applications and is suitable for multiple industries such as the grain, chemical, and mining industries.

Customizable Equipment Options

Besides factory – standardized equipment, customized products can also be provided according to customers’ requirements, such as super – large – scale equipment, brands of electrical components, packaging range, and conveyor length.