In today’s fast-paced industrial world, efficient waste management and recycling solutions are more important than ever. Single shaft shredders have become a cornerstone in processing various materials, from plastics and rubber to metals and electronic waste. As a manufacturer with 23 years of experience in the industry, we specialize in producing high-quality single shaft shredders, duble shaft shredders, packaging machines, and copper wire recycling machines. Our expert R&D team ensures that every machine meets the highest standards of performance and durability.

In this comprehensive guide, we’ll explore:

– What a single shaft shredder is and how it works

– Key applications across industries

– Benefits of choosing a custom-designed shredder

– How our 23 years of expertise can help you find the perfect solution

What Is a Single Shaft Shredder?

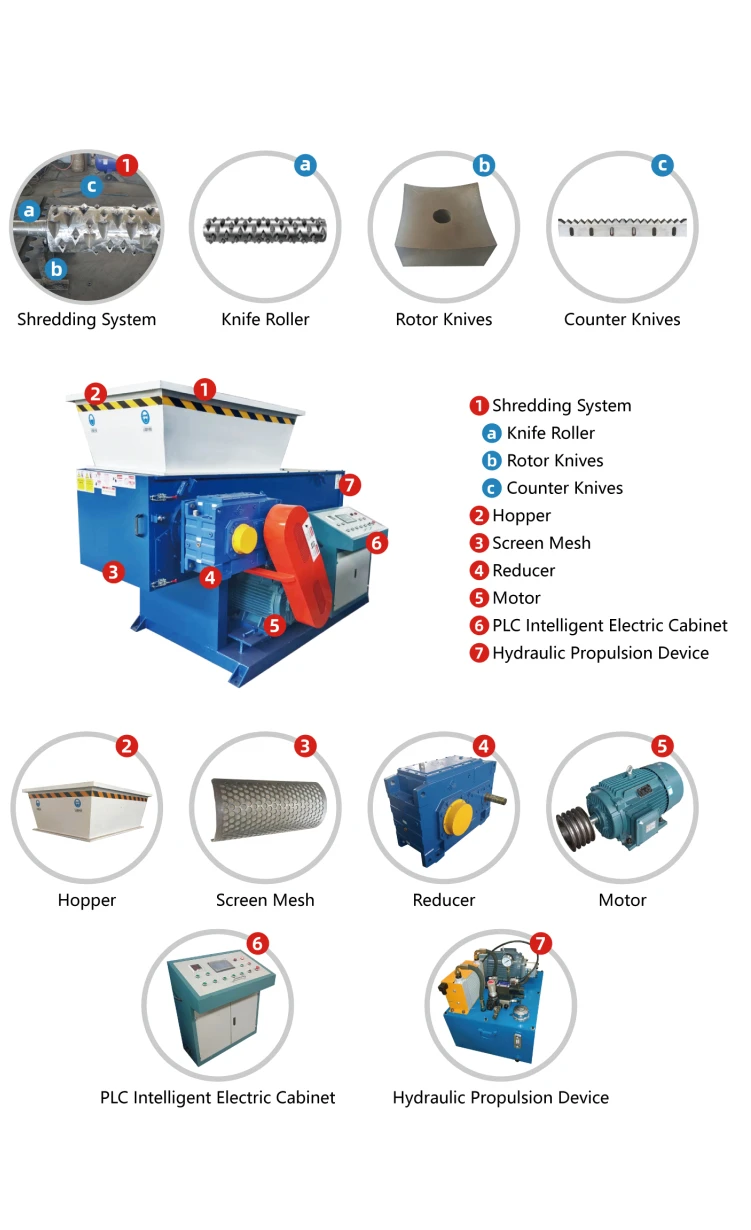

A single shaft shredder is a powerful industrial machine designed to break down bulky materials into smaller, manageable pieces. It consists of a rotating shaft with blades that cut, tear, and crush materials fed into the hopper. These machines are widely used in:

– Plastic recycling (bottles, films, pipes)

– Tire recycling (rubber shredding for reuse)

– E-waste processing (circuit boards, cables)

– Wood processing (pallets, furniture scraps)

– Metal recycling (aluminum, copper, steel)

Unlike dual shaft shredders, which use two interlocking shafts, single shaft models provide high torque and precision cutting, making them ideal for tough materials.

Why Choose a Single Shaft Shredder?

1. High Efficiency & Durability

Our single shaft shredders are built with premium-grade steel blades and robust motors to ensure long-lasting performance, even under heavy workloads.

2. Customizable Solutions

Every business has unique requirements. Whether you need different blade configurations, varying hopper sizes, or specialized motor power, we can customize the shredder to fit your exact needs.

3. Lower Maintenance Costs

With a simple yet sturdy design, single shaft shredders require less maintenance compared to more complex machines, reducing downtime and operational costs.

4. Versatile Material Processing

From soft plastics to hard metals, our shredders can handle a wide range of materials, making them a cost-effective investment for recycling plants and manufacturing facilities.

Applications of Single Shaft Shredders

1. Plastic Recycling

Single shaft shredders efficiently process PET bottles, HDPE containers, and PVC pipes into uniform flakes for further recycling.

2. Tire Shredding

Used tires are shredded into rubber crumbs, which can be repurposed for playground surfaces, asphalt, or new tire production.

3. E-Waste Disposal

Electronic waste, including circuit boards, cables, and hard drives, is safely shredded to recover valuable metals like copper and gold.

4. Metal Scrap Processing

Aluminum, copper, and steel scraps are reduced in size for easier melting and reuse in manufacturing.

5. Wood & Biomass Shredding

Wood pallets, furniture waste, and agricultural residues are shredded for use in biomass energy production.

Our Expertise: 23 Years of Innovation

With Forceshredderover two decades of experience, our factory has developed advanced shredding technologies tailored to global clients. Here’s why businesses trust us:

✅ Professional R&D Team – Continuous innovation ensures cutting-edge performance.

✅ Custom Manufacturing – We adjust blade speed, chamber size, and power based on your material type.

✅ Global Supply – Reliable machines shipped worldwide with after-sales support.

✅ Competitive Pricing – High-quality shredders at cost-effective rates.

How to Choose the Right Single Shaft Shredder

When selecting a shredder, consider:

✔ Material Type – Hard metals require stronger blades than plastics.

✔ Output Size Needed – Adjustable screen sizes control shredded particle dimensions.

✔ Production Capacity – Higher horsepower motors handle larger volumes.

✔ Automation Features – Some models include conveyor belts or sorting systems.

Need help deciding? Our engineers can recommend the best model based on your daily processing needs.

Conclusion

A single shaft shredder is an essential machine for efficient waste reduction and material recovery. Whether you operate a recycling plant, a manufacturing facility, or a waste management company, investing in a custom-designed shredder can significantly improve productivity and sustainability.

With 23 years of industry expertise, we provide top-quality, customizable shredding solutions tailored to your business.