Client Needs & Solution:

A Russian metal recycling company needed to process 8 tons/hour of mixed aluminum cans and beverage containers. Key challenges included:

- Removing lacquer coatings during shredding

- Preventing material wrapping around shafts

- Achieving uniform 30-50mm output for smelting

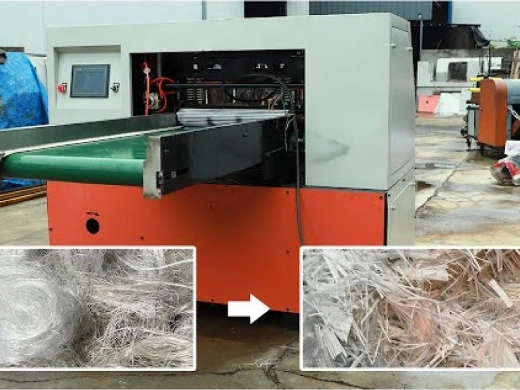

Our double shaft shredder (Model FD-1400) demonstrated during their factory visit provided the ideal solution with:

- Anti-wrapping rotor design with special hook-shaped blades

- Integrated air separation to remove paper/labels

- Hardened steel cutters for extended 6-month lifespan

- Equipped with two 45kW high-performance motors

Operational Results:

- 9.2 tons/hour processing capacity

- 98% pure aluminum output after eddy current separation

- 30% lower energy consumption vs. hammer mills

- 24/7 operation capability with <1% downtime

This project showcases our expertise in metal shredding solutions for Russia’s growing recycling industry, particularly for beverage container recycling applications.